ABB and Purple Hat have prolonged their collaboration to develop automation techniques for the way forward for industrial IT, enabling safer and modular deployment of management functions for course of industries.

The collaboration builds on ABB’s automation management and Purple Hat’s industry-leading enterprise open supply platforms, combining industrial innovation and digital capabilities – together with information analytics and synthetic intelligence – to assist pave the best way in direction of autonomous operations.

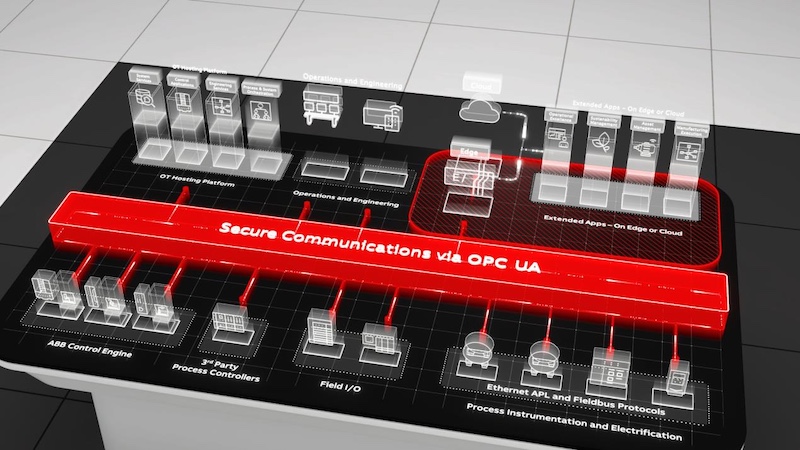

ABB’s course of automation system structure consists of two interconnected but distinct environments: a sturdy and safe management setting that helps guarantee secure, real-time administration of vital processes, and a digital setting designed for versatile and scalable introduction of digital options.

Beforehand, ABB and Purple Hat collaborated on the digital setting infrastructure for a extra fast scalable deployment of superior analytics, synthetic intelligence and cloud-based functions, with out disrupting core management operations.

Now, the 2 corporations are increasing their collaboration to incorporate the management setting, delivering enhanced operational consistency and stability to satisfy probably the most demanding safety and course of necessities.

Constructed on Purple Hat platforms equivalent to Purple Hat System Edge and Purple Hat OpenShift this twin method will enable prospects to introduce improvements incrementally, defending operational integrity and current investments whereas sustaining excessive ranges of cybersecurity.

Moreover, Purple Hat applied sciences present a dependable and safe basis for system lifecycle providers throughout the course of automation system.

Stefan Basenach, senior vice chairman, course of automation know-how, ABB, says: “Ongoing {industry} collaboration is crucial to shaping the way forward for automation.

“Along with Purple Hat, we’re advancing modular, scalable options that align with international frameworks and ship long-term worth to prospects throughout course of industries.

“The twin-layered structure, constructed on open supply platforms, creates a sturdy basis for the {industry} to progress in direction of autonomous operations.

“We stay up for constructing on this momentum collectively as we proceed to drive open, resilient and safe automation that helps {industry} each now and sooner or later.”

Francis Chow, vice chairman and basic supervisor, Purple Hat in-vehicle working system and edge, Purple Hat, says: “This prolonged collaboration with ABB marks a big milestone for the {industry} at giant, as we empower producers with the instruments and options they should remodel to higher meet the calls for of right now’s more and more advanced industrial panorama.

“Purple Hat platforms, together with Purple Hat System Edge and Purple Hat OpenShift, present a sturdy and constant basis for course of automation and industrial controls, serving to to handle the strict safety and uptime necessities of business use circumstances.

“We stay up for persevering with our work with ABB to ship fashionable automation powered by open supply applied sciences.”

Aligned with international {industry} requirements and frameworks, ABB and Purple Hat’s collaboration helps safe adoption throughout multi-vendor environments, permitting prospects to embrace digital transformation with larger confidence.