Superior remedy (ATMP) builders want to hunt a stability between the dangers and advantages of utilizing closed techniques. That’s the view of David Estapé, PhD, know-how supervisor at CRB Group.

In accordance with Estapé, who has 25 years’ expertise in facility design and consulting on business manufacturing, firms might be overly cautious in deciphering regulator issues about applied sciences, typically overestimating tiny dangers and never contemplating the advantages of enhancing supply to sufferers.

“If you happen to don’t know the chance of a nasty end result, and also you throw away the product, everybody stays of their consolation zone, however the affected person continues to be ready for drugs!” he explains. “I’m not saying we should always take dangers with merchandise or affected person security, but it surely’s essential to worth chance and do a threat evaluation.”

Navigating regulatory challenges

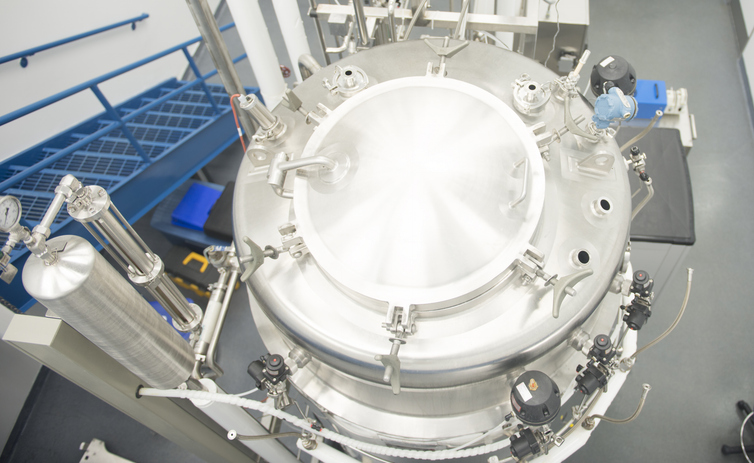

Estapé can be talking about navigating regulatory challenges at Bioprocessing Summit Europe in Barcelona later this month. His speak focuses on closed processing which, he says, is the place a course of is remoted from the encircling room. This enables the method to be faraway from a cleanroom, which can permit firms to raised standardize and scale up ATMP manufacturing to deal with tens of hundreds of sufferers, somewhat than the few hundred typically handled right now, he provides.

“Isolating the method from the room atmosphere is likely one of the key issues that can permit us to maneuver to the manufacturing of the longer term, particularly in personalised drugs,” he explains.

Sadly, though closed techniques have an extended historical past, in accordance with Estapé. Their adoption has been sluggish attributable to regulator’s definitions of the know-how changing into longer, extra prescriptive, and detailed. “Regulatory issues, particularly about single use, have made it tougher to go away the cleanroom,” he explains.

Nonetheless, he doesn’t blame the regulators for slowing adoption. As a substitute, he says, firms can overinterpret a regulator’s issues concerning the threat of a pinhole in a single-use plastic tube or of a connector not connecting correctly.

As a substitute of contemplating the probability that of a threat to the product, firms could determine as a substitute to stay with current applied sciences, e.g., clear rooms, thereby lowering their skill to fulfill the wants of sufferers, each now and sooner or later.

“I don’t need to joke about such critical points,” he factors out. “However it’s just like the meteor that [might have a] 3.1% probability of hitting Earth. A couple of weeks later the chance is sort of negligible. If this had been the pharma business, we might have already constructed bunkers.”